TRAY SEALERS

Heat sealing machines are packaging machines for sealing roll film (polypropylene, polyester, or other plastic films) onto preformed plastic trays; the ability to vacuum inside the container and feed inert gases (protective atmosphere) makes it the most widely used packaging machines in food packaging.

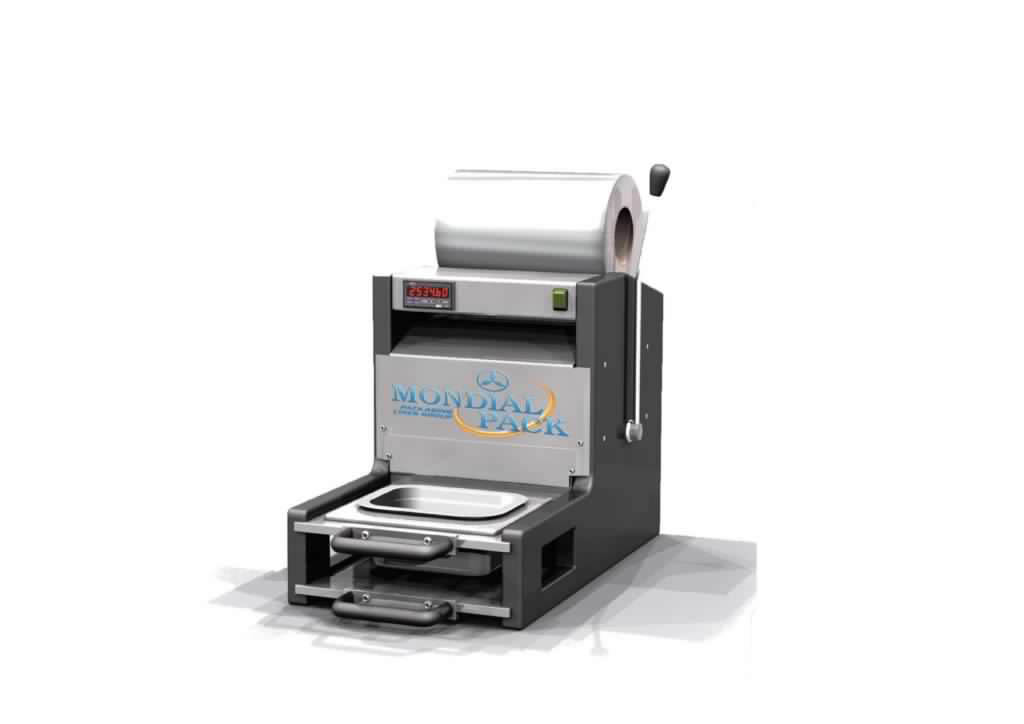

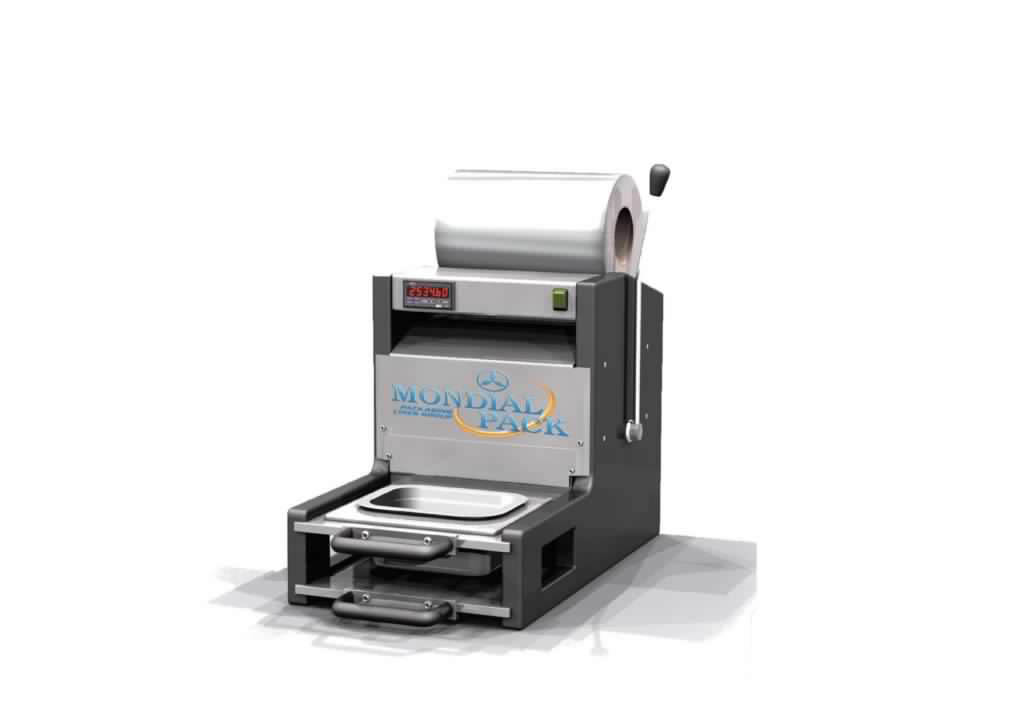

BENCHTOP THERMOSEALING MACHINE

SF 200/250/350/550 DA BANCO

Manual hermetic thermosealing machine with rapid mold change. Minimum maintenance. Ideal for small delicatessens, catering, ready meals administration.

- Made of stainless steel, bestseller of our manual hermetic thermosealing machines.

- Ideal for small delis, catering, ready meal administration

- Easy to use

- Quick mold change

- Minimal maintenance

MTS 200

MTS 200

MODEL MTS 200 Semi-automatic thermosealing machine for preformed trays

Structure: stainless steel and anodised aluminium frame

Control panel: PLC Mitsubishi and Touch Screen

Automatic film advancement with waste winder

Closing trays film in continuous feed

Automated to avoid contact hands-film

Hight trays: standard 110 mm , on request 150 mm

Sealing area dimensions: 410 x310 mm

Max film dimensions: 500 mm

Fast mould change

Automatic piston for drawer opening and closing

Trays expulsion system at the end of cycle to help

Trays shape cutting

Output (according to product): till 7-8 cycles/min (seal.) and till 3-4 cycles/min (vacuum+gas)

Vacuum pump: 100 mc

Voltage: 400V-3Ph+N+earth

Power: 2/5 Kw

Protection class: IP 65

Compressed air: 6/7 bar

Weight: 230 kg

Machine dimensions: L1350xP710xH1550 mm

Standard Ethernet connection

Optionals : vacuum system, gas flushing, skin

ATS 30

ATS 30

MODEL ATS 30. Automatic traysealing machine

Structure: AISI 304 stainless steel and anodized aluminum frame

Control panel: PLC Mitsubishi and Asem touch screen

Trays advancement managed by inverter with encoder

2 standard loading stations

60 mc pump (only vacuum/gas version)

Mould max dimensions: 340 x 280 mm

Max tray dimensions with 1 impression mould: 325 x 265 mm

Max tray dimensions with 2 impressions mould: 260 x 150 mm

Max trays height: 80 mm

Max width of the film 440 mm.

Max film reel diameter 250 mm.

Machine dimensions: L2400xp780xH1700 mm

Discharge of packed trays with stainless steel rollers

Standard Ethernet connection

Protection class: IP 65

Voltage: 400V-3Ph-50Hz+N+earth

Power: 3,5 Kw

Pneumatic feeding: 6 bar Compressed air

Max Weight: 500kg

Output (according to product): vacuum gas till 3-4 cycles/min./ only vacuum till 5-6 cycles/min, only sealing till 7-8 cycles/min

ATS 42

ATS 42

MODEL ATS 42 Automatic thermosealing machine only sealing with lower chamber subdivided in 2 lines

Structure: AISI 304 stainless steel and anodised aluminium frame

Fixed Control panel: Mitsubishi PLC and Asem touch screen

Trays advancement by Brushless motor

Loading site with rods belt with double step

Sealing area dimensions: 430×320 mm divided in half

Max trays higth: 100 mm standard

Max dim. mould: 430×320 mm

Fast change of mould

Discharge of packed trays with stainless steel rollers

Max film dimensions: 500 mm

Output (according to product): till 10-12 cycles/min

Output: from 400 to 2880 trays/hour

Voltage: 400V-3Ph-50Hz+N

Power: 2.5 Kw

Weight: 500 kg

Protection class: IP 65

Pneumatic feeding: 6 bar compressed air

Machine dimensions: L3020xP1050

ATS 50

ATS 50

MODEL ATS 50 Automatic Thermosealing machine

Structure: AISI 304 stainless steel and anodised aluminium frame

Fixed Control panel: Mitsubishi PLC and Asem touch screen

Trays advancement by Brushless motor

Loading site with rods belt 100 mc Busch pump (only vacuum+gas version)

Sealing area dimensions: 400×300 mm

Trays height: 100 mm standard

Fast change of mould

Discharge of packed trays with stainless steel rollers

Max film dimensions: 500 mm

Output (according to product): till 10 cycles/min (only sealing) and till 8 cycles/min (vacuum gas)

Output: from 400 to 2880 trays/hour

Voltage: 400V-3Ph-50Hz+N

Power: 5.5 Kw

Protection class: IP 65

Pneumatic feeding: 6 bar compressed air

Machine dimensions: L3020xP1050xH2000 mm

Weight: 620 kg

DTS 38/40/42

DTS 38/40/42

MODEL DTS 38 Thermosealing machine

Structure: AISI 304 stainless steel and anodised aluminium frame

Fixed Control panel: Mitsubishi PLC and Asem touch screen

Trays advancement by Brushless motor

Loading site with rods belt

100 mc pump (only vacuum+gas version)

Sealing area dimensions: 400x 130 mm x 2

Max trays height: 80 mm

Fast change of mould

Discharge of packed trays with stainless steel rollers

Max film dimensions: 490 mm

Output (according to product): till 10 cycles/min (only sealing)+8 cycles/min (vacuum gas)

Output: from 400 to 3600 trays/hour

Voltage: 400V-3Ph-50Hz+N

Power: 5.5 Kw

Weight: 620 kg

Protection class: IP 65

Pneumatic feeding: 6 bar compressed air

Machine dimensions: 3020x1050x2000 h

THERMOFORMING MACHINE

THERMOFORMING MACHINE

Thermoforming machines are packaging machines that, starting with two reels of film first form the tray then, after filling, heat-seal it.

Thermoforming machines give the ability to feed modified atmosphere into the package.

They are suitable machines for medium to large production because they cut down costs for the bottom part of the package (tray).Thermoforming packaging machine is made of stainless steel,

in line with hygiene and food safety. Durable transmission chain can cut the film more than 2 million times. Equipped with touch screen and multilingual PLC.

Possible connection with automatic filling machine, thermal date printing, easy to tear film. Simple and easy change for die sets; Customized die size. Automatic warning for insufficient film supply.

High-speed production can greatly reduce labor costs. It can be used to package powder, paste, solid and liquid materials. We also offer a variety of options for this machine.

TF XLM

TF XLM

TF XLM COMPACT AUTOMATIC TRAY SEALERS

AISI304 stainless steel and anodised aluminium frame

AISI304 stainless steel panelling

Trays feeding and positioning through inverter

Injection system for inert gas

Overpressure system for inert gas injection

Feeding area

Automatic exit of sealed trays

Control panel

PLC-based control system

Possibility of pogramming 12 different production cycles

Quick and easy die replacement

160 – 250 mc/h internal vacuum pump

Collegamento Elettrico (V) 380

Potenza installata (Kw) 5

Fascia Massima Bobina 500

Produttività (pezzi/ora – Kg/ora – L/ora – cicli/min) SIGILLATURA: 9/12 Cicli Minuto

GAS INJECT: 8/9 Cicli al Minuto

Dimensioni (H x L x P) 1500 X 1360 X 1460 mm

Peso macchina (Kg) 700

MIDIMEC AUTOMATIC

MIDIMEC AUTOMATIC

MIDIMEC Automatic heat-Sealer

General features

AISI 304 stainless steel and aluminium anticorodal structure

AISI 304 stainless steel side panels

Mechanical movements of all working cycles, including sealing, that is made through servomotor, without compressed air

The following production cycles can be easily programmed through PLC :

1. only sealing

2. sealing with vacuum + gas MAP

3. Gas injection (without vacuum pump)

4. Skin – packaging

Easy change of the mould for different tray sizes

Integrated vacuum pump 25 mc/h

Speed:

– only sealing: from 9 up to 12 cycles /minute

– gas inject: from 6 to 8 cycles/minute

– vacuum + gas “MAP”: from 3 to 5 cycles/minute

Max mould dimension 400 x 300 x h 120 mm standard

Max trays dimensions:

Single tray: mm 380 x 280

Two trays: mm 195 x 280

Three trays side by side: mm 125 x 280

Four trays side by side: mm 95 x 280

Collegamento Elettrico (V) 380V

Potenza installata (Kw) 3

Fascia Massima Bobina 500 mm

Dimensioni Ingombro 1300 x 900 x 1560 mm

Frequenza (Hz) 50

Produttività (pezzi/ora – Kg/ora – L/ora – cicli/min) 3 – 12 cicli/minuto

XS MEC AUTOMATICA

XS MEC AUTOMATICA

TRAY SEALERS XS MEC AUTOMATIC

MAIN FEATURES:

– Main structure in Stainless steel AISI 304/Alluminium Anticorodal

– Side panels in Stainless steel AISI 304/Alluminium Anticorodal

– Mechanical movements of all the working cycles – including sealing – made through servomotor without compressed air

– Gas injection device

– Vacuum pump 25 m3/h

– Easy and quick mould substitution

– The following production cycles can be easily programmed through the PLC :

1)Only sealing

2)Sealing with vacuum + gas MAP

3)Gas inject (without vacuum pump)

4)Skin packaging

SPEED for 1 and 4 tray mould:

Speed without MAP (only sealing) : 400 – 1200 trays per hour

Speed with gas injection system: 240 – 960 trays per hour

Speed with vacuum MAP : 200 – 800 trays per hour

Collegamento Elettrico (V) 380

Potenza installata (Kw) 1

Frequenza (Hz) 50

Produttività (pezzi/ora – Kg/ora – L/ora – cicli/min) 200/1200 vaschette/ora

Fascia Massima Bobina 500mm

Peso macchina (Kg) 150

Dimensioni (H x L x P) 1500mm x 650mm x 1000mm

XLM MEC AUTOMATICA

XLM MEC AUTOMATICA

TRAY SEALER XLM MEC AUTOMATIC

AISI 304 stainless steel and aluminium anticorodal structure

AISI 304 stainless steel side panels

Mechanical movements of all working cycles, including sealing, that is made through

servomotor, without compressed air

The following production cycles can be easily programmed through PLC :

1. only sealing

2. sealing with vacuum + gas MAP

3. Gas injection (without vacuum pump)

4. Skin – packaging

Feeding area

Automatic ejection of the packed products

Easy change of the sealing mould

Integrated vacuum pump 100 m3/h

Collegamento Elettrico (V) 380

Frequenza (Hz) 50

Consumo elettrico (Kw/h) 5

Fascia Massima Bobina 500mm

Produttività (pezzi/ora – Kg/ora – L/ora – cicli/min) Solo sigillatura da 9/12 Cicli Minuto

Gas inject da 8/9 Cicli Minuto

Vuoto + gas “MAP” 5/6 Cicli Minuto

Dimensioni Massime Confezioni stampo 400x500mm H120mm